Aeronautical Production Engineering addresses the needs of production optimization in the aeronautical industry, considering the different phases that take place in the production environment, from requirements gathering, analysis and management; product and process design and modeling design and modeling of products and processes; production phases; and validation and verification phases. verification phases. All of this not only from the point of view of production optimization, but also from the but also addressing the increasingly important aspect of sustainability.

Information and Communication Technologies (ICT) and Artificial Intelligence (AI) have brought about a new industrial revolution, having a significant impact on industry and transforming the way companies operate and compete. Nowadays, in the industrial world, advanced production techniques are combined with intelligent technologies to optimize industrial processes, such as manufacturing, logistics, monitoring and integration of processes and systems, and supply chain management used in organizations. This is what is known in the literature as Industry 4.0. Industry 4.0 is committed to greater automation, connectivity and globalization, and uses technologies such as robotics, big data, AI and the Internet of Things (IoT) to achieve more efficient and optimized production procedures.

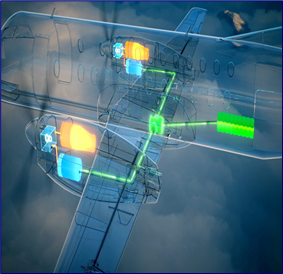

The main objective of the project is to develop a digital platform to provide smart and efficient solutions to optimize engineering services for the aeronautical sector. The secondary objectives of the project, in which the research group is involved, are:

- Analyze the state of the art of the use of Big Data and Deep Learning technologies in the aeronautical production systems.

- Definition of a Model-based systems engineering (MBSE) for and optimal data management.

- Definition of methodologies to evaluate, visualize and interpret data.

- Suport the development of communication protocols and analysis procedures of system monitoring signals.